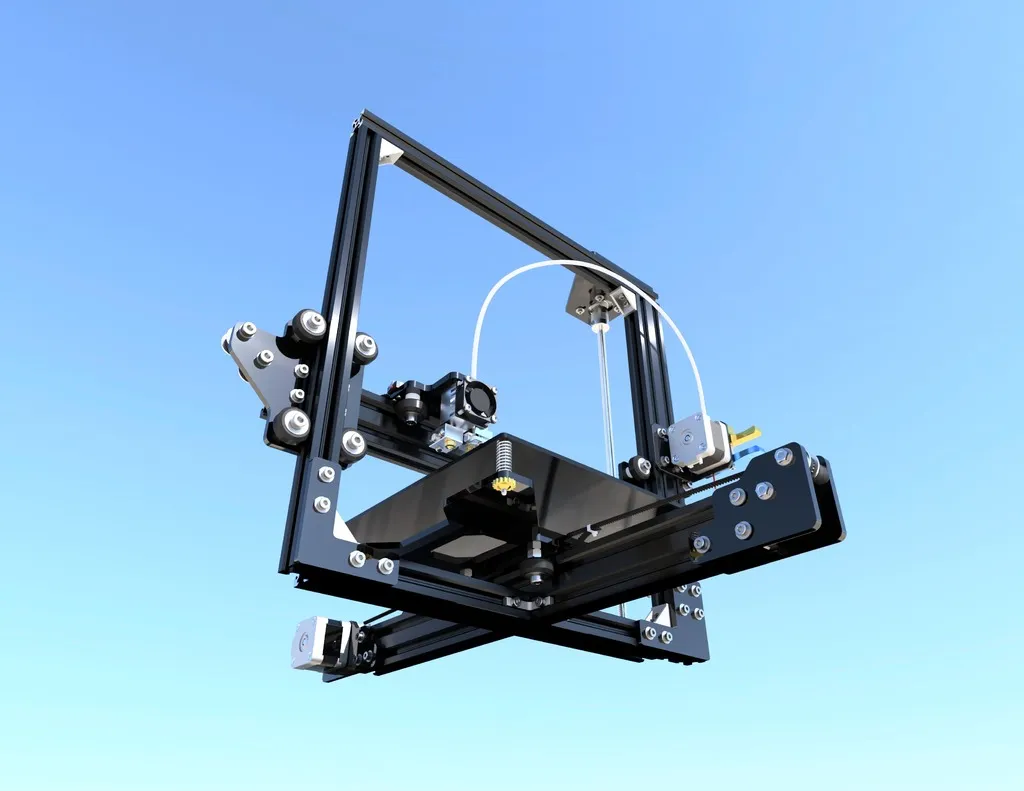

What is VREF and Why is it Important for Your Tevo Tarantula?

VREF, or Voltage Reference, is a critical setting on your Tevo Tarantula 3D printer that directly influences the performance of your stepper motors. These motors are the heart of your printer’s movement system, controlling the X, Y, and Z axes, as well as the extruder. The VREF setting determines the amount of current supplied to these motors. Adjusting VREF correctly ensures your stepper motors receive the appropriate power, allowing them to function smoothly and accurately. Incorrect VREF settings can lead to a variety of printing problems, including skipped steps, overheating, and poor print quality. Understanding and correctly setting VREF is essential for maximizing the potential of your Tevo Tarantula and achieving optimal 3D printing results. Furthermore, it is a relatively simple adjustment that can significantly improve your printing experience.

Understanding Stepper Motors and VREF

Stepper motors are unique because they move in discrete steps rather than continuously. This precision allows the printer to accurately position the print head and bed. VREF plays a crucial role in controlling the current supplied to these stepper motors. Stepper motor drivers, small electronic components on the printer’s motherboard, regulate the current. VREF sets the upper limit of the current these drivers provide. If the VREF is too low, the motors might not receive enough power to move the axes or extrude filament effectively, resulting in missed steps and under-extrusion. If VREF is too high, the motors might overheat, potentially damaging the drivers or the motors themselves and impacting print quality. Properly setting the VREF is a balance, ensuring sufficient power without causing adverse effects.

The Role of VREF in Stepper Motor Control

VREF directly influences the torque and speed capabilities of your stepper motors. Torque refers to the rotational force of the motor, determining its ability to move the axes against resistance. Speed, on the other hand, is the rate at which the motor turns. A higher VREF generally allows for greater torque and potentially higher speeds, but it also increases the risk of overheating. When the printer is printing, the motors need enough torque to move the print head and bed, especially during rapid movements. Furthermore, the extruder motor needs sufficient torque to push the filament through the nozzle. VREF settings need to be carefully balanced to provide sufficient power for all these functions without causing the motors to overheat. Finding the optimal VREF settings enables the printer to run smoothly, accurately, and reliably.

Tools and Materials You’ll Need for VREF Adjustment

Before adjusting the VREF on your Tevo Tarantula, gather the necessary tools and materials to ensure a safe and accurate process. This preparation will make the calibration process much smoother. You will need a multimeter, which is essential for measuring the voltage. A small screwdriver, ideally a non-magnetic one, is needed to adjust the VREF potentiometers. These are small adjustable resistors on the stepper motor drivers. A set of precision screwdrivers might also be helpful. Also, it’s recommended to have a small insulated container or a non-conductive surface to place the multimeter probes to avoid short circuits. Finally, having the printer’s manual or any documentation handy can be useful for identifying the location of the VREF potentiometers on the board.

Essential Tools for VREF Calibration

The most crucial tool for VREF calibration is a multimeter. Digital multimeters are preferred for their ease of use and accuracy. Ensure your multimeter is set to measure DC voltage. When selecting a multimeter, choose one with a resolution that can accurately measure to two or three decimal places. Make sure to have the correct probes. In addition to the multimeter, you’ll need a small, non-magnetic screwdriver or a plastic adjustment tool. The VREF potentiometers are tiny and sensitive, so using the correct tool helps to prevent accidental damage. A well-lit workspace and a magnifying glass or a jeweler’s loupe can also be helpful. This is particularly useful if you’re working with older or smaller printer boards where the components are tightly packed. Moreover, safety glasses are always recommended when working with electronics to protect your eyes.

Safety Precautions Working with Electronics

Safety should be your primary concern when working with electronics like your Tevo Tarantula. Always disconnect the printer from the power source before making any adjustments to the electronics, including VREF calibration. This prevents the risk of electric shock and protects the printer components from potential damage. Be careful when handling the motherboard and other sensitive components to avoid electrostatic discharge (ESD). It’s advisable to work on an anti-static mat and ground yourself before touching any components. Avoid touching any components while the printer is powered on. If you are unsure about any part of the process, consult the printer’s manual or seek help from an experienced 3D printing enthusiast. Moreover, regularly inspect the wiring and components for any signs of damage or wear before starting the calibration.

Step-by-Step Guide to Adjusting VREF on Your Tevo Tarantula

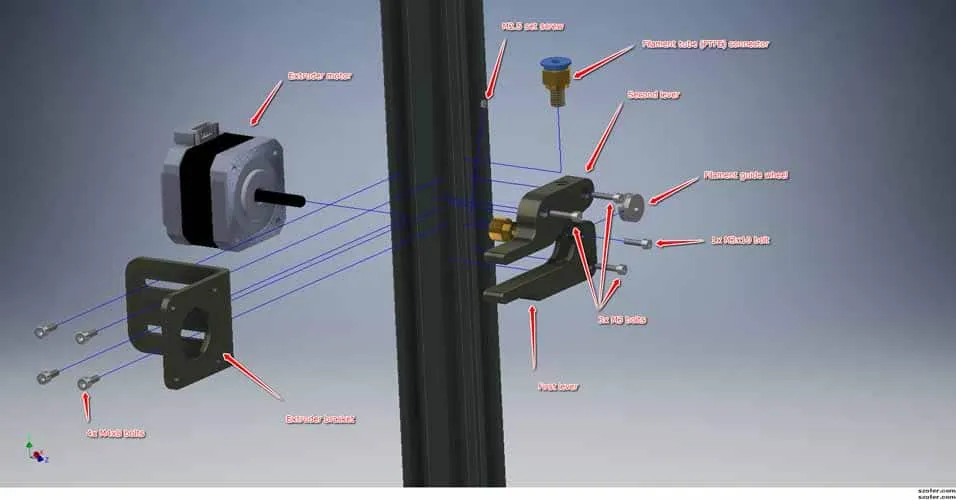

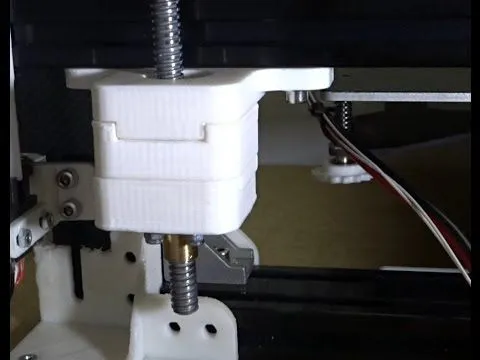

Follow this step-by-step guide to adjust the VREF on your Tevo Tarantula. First, power off and unplug the printer. Locate the stepper motor drivers on the mainboard. These are the small modules with the potentiometers. They are responsible for controlling the stepper motors. Using the multimeter, measure the voltage across the potentiometer on each stepper motor driver. Carefully insert the multimeter probes. The probes should touch the small test points near the potentiometer. Use the small screwdriver to adjust the potentiometer. Turn it slowly and check the voltage frequently. Adjust the VREF for each axis (X, Y, Z, and extruder) and save your new settings. After adjusting, power on the printer and test the movement of each axis. Monitor the motor temperature during the initial tests.

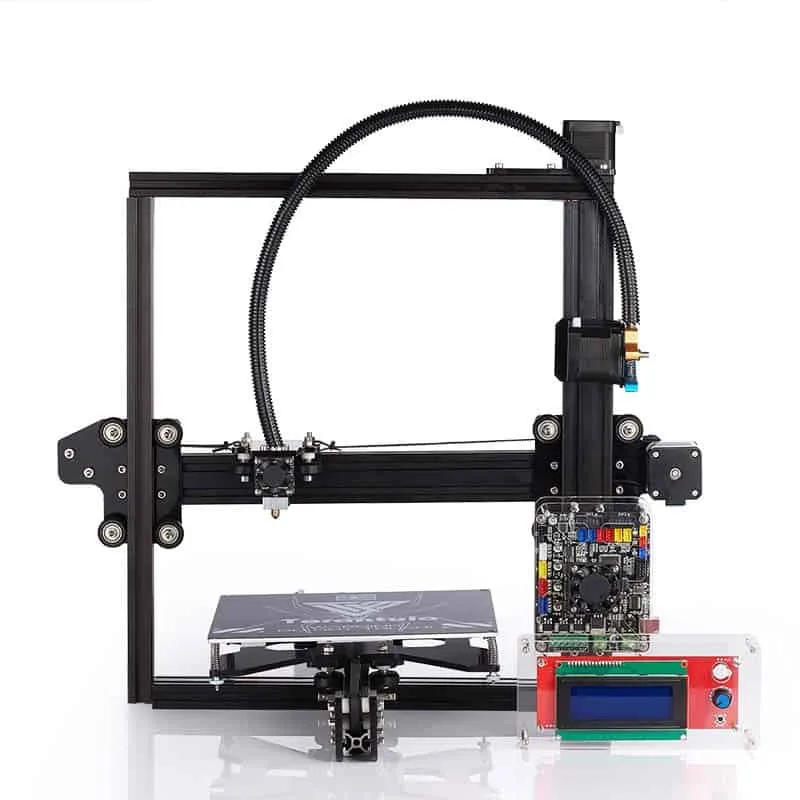

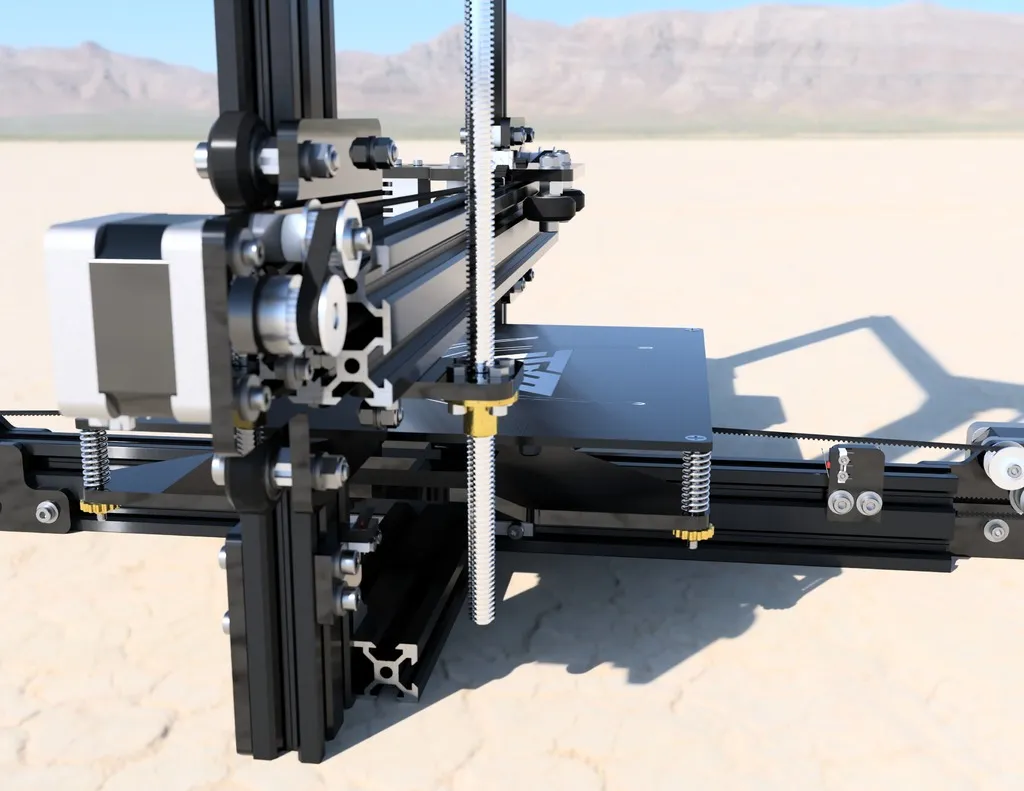

Locating the Stepper Motor Drivers

Identifying the location of the stepper motor drivers on your Tevo Tarantula is a crucial first step. The mainboard, usually housed in a control box, is where you’ll find these components. The stepper motor drivers are typically small, square modules with a small potentiometer (a screw that you can turn) on top, used for adjusting the VREF. The drivers are usually labeled with their axis (X, Y, Z, and E for the extruder). If you are unsure, consult the Tevo Tarantula’s manual or search for diagrams online that show the layout of the mainboard. Make sure to handle the board with care, avoiding any static electricity, as these components are sensitive.

Using a Multimeter to Measure VREF

Using a multimeter correctly is essential for an accurate VREF adjustment. Set your multimeter to measure DC voltage. Locate the small test points on the stepper motor driver, which are usually marked near the potentiometer. Place the red probe on the test point and the black probe on the GND (ground) pin, which is often located near the power supply connector or on the mainboard. The multimeter will display the current VREF value. Be extremely careful not to touch any other components while taking a reading, as this could damage the multimeter or the printer. Take the measurement when the printer is turned off. Remember that this will be the initial reading before you begin to adjust.

Precise VREF Adjustment How to Calibrate

Fine-tuning the VREF is a matter of careful adjustment and testing. After measuring the initial VREF, use a small screwdriver to gently turn the potentiometer. Small adjustments are key. Turning the potentiometer clockwise typically increases the VREF, while turning it counterclockwise decreases it. After each small adjustment, re-measure the voltage with your multimeter. Repeat this process, making tiny adjustments and taking measurements. Adjust the voltage in small increments of 0.01V or 0.02V. Keep a record of your adjustments for each axis. Test the printer after each adjustment to ensure that the motors function smoothly without overheating or skipping steps. The goal is to find the setting where the motor operates efficiently without getting excessively hot.

VREF Values What to Expect

The optimal VREF values vary depending on your specific Tevo Tarantula setup, including the type of stepper motor drivers, the motors themselves, and the modifications you’ve made to your printer. However, there are some general guidelines to consider. For most Tevo Tarantula printers, the VREF typically ranges from 0.6V to 1.2V. Check the specifications of your stepper motor drivers and motors. If possible, consult the manufacturer’s recommendations for VREF settings. Start with lower values and increase the VREF incrementally while monitoring the motors for any issues. Remember that higher VREF settings provide more power but also increase the risk of overheating. Carefully testing and monitoring the motors are critical to finding the ideal settings.

Calibrating VREF for X, Y, and Z Axes

The X, Y, and Z axes of your Tevo Tarantula control the movement of the print head and the bed. Adjusting VREF for these axes is essential for ensuring that your prints are accurate and consistent. First, identify the stepper motor drivers that control the X, Y, and Z axes on your mainboard. Then, measure and adjust the VREF for each driver individually. Start with the X and Y axes. These are responsible for the horizontal movement of the print head. You want these motors to move smoothly and quickly without skipping steps. The Z-axis controls the vertical movement of the print bed. This axis usually requires less current than the X and Y axes, but it is still crucial to prevent the bed from moving erratically. After each adjustment, test the movement of the corresponding axis. The goal is to achieve smooth, precise movements without overheating.

Calibrating VREF for the Extruder

The extruder motor is crucial for pushing the filament through the hot end, and it requires careful VREF calibration. Identify the extruder motor driver on your mainboard. The extruder is also known as the E axis. Measure and adjust the VREF for this driver. The extruder motor needs enough torque to reliably push the filament without skipping steps or grinding. Start with a low VREF and slowly increase it until the extruder consistently pushes filament. Be careful not to set the VREF too high, as this can cause the motor to overheat or damage the filament. Test the extruder by preheating the nozzle and extruding filament manually. Observe the flow of the filament to check for any problems.

Troubleshooting Common VREF Issues

Even after calibrating VREF, you might encounter issues. Understanding and knowing how to fix them will help you to optimize the printer. One of the most common issues is overheating stepper motors. If the motors become too hot to touch, the VREF may be set too high. Reduce the VREF setting. Another common issue is skipped steps or layer shifting. This usually indicates that the motors are not getting enough power. Increase the VREF setting. Noise can also be a sign of a problem. Excessive motor noise might indicate that the VREF is set too high. Make small adjustments and test the printer. If you have print quality problems, such as inconsistent extrusion or poor layer adhesion, these may be related to incorrect VREF settings. By systematically working through the adjustments, you can typically resolve most issues.

Overheating Stepper Motors

Overheating is a significant concern because it can cause various problems. If you notice the stepper motors on your Tevo Tarantula are very hot to the touch, the VREF is likely set too high. This excess heat can lead to damage to the motors or the stepper motor drivers, potentially causing the printer to malfunction. To address this, carefully reduce the VREF setting. Make small incremental decreases to the VREF value and monitor the motor temperature after each adjustment. Ensure good ventilation around the motors. If the motors continue to overheat, check your cooling fans to ensure they are functioning properly. Excessive heat is an indicator that something is wrong. Regularly check the motors, especially during longer prints, and make adjustments if necessary to optimize performance.

Skipped Steps and Layer Shifting

Skipped steps and layer shifting are common issues. They often indicate that your stepper motors are not receiving enough power to move the axes accurately, resulting in inconsistent prints. Skipped steps manifest as areas where the print head or bed fails to move as commanded, causing gaps or misaligned layers. Layer shifting shows the entire printed object shifting position mid-print. If you encounter these problems, start by increasing the VREF setting. Increase the VREF in small increments. Make adjustments and test the movement of the affected axis. Monitor the print quality. If this issue persists, check other possible causes, such as mechanical issues. Loose belts or obstructions can cause these symptoms, as well. Ensure all belts are tight and aligned and that the axes move freely.

Fine-Tuning and Optimization for Optimal Performance

Fine-tuning your VREF settings is a process of continual improvement. Once you have the basic settings dialed in, you can optimize them for more specific printing tasks and materials. Different filaments might require different VREF settings, and you may need to adjust them based on the filament you are using. For example, flexible filaments might require lower VREF settings on the extruder to prevent the filament from jamming. Consider using test prints. Print small calibration objects and assess the print quality to identify and fix any issues. Keep a log of your VREF settings and the corresponding print results for various materials. With practice, you will develop a better understanding of how to get the best results from your Tevo Tarantula. This is important because optimizing for the best performance means finding the right balance.

Monitoring and Adjustments

Regular monitoring of your Tevo Tarantula is essential to maintain the optimal VREF settings and ensure consistent print quality. As you print, pay attention to any signs of problems, such as overheating motors, skipped steps, or layer shifting. Periodically check the temperature of the motors, especially during longer prints. Keep track of the types of materials you are printing with, as well as the speeds and temperatures. Make adjustments to the VREF settings if you notice any issues. Over time, components like belts and bearings wear out, which can also impact your VREF settings. Make sure the physical components are working properly. By regularly monitoring and making necessary adjustments, you can keep your printer running smoothly and optimize the life of your printer.

Maintenance and Regular Checks for VREF

Regular maintenance is crucial for the overall performance of your 3D printer, and this also includes the VREF settings. The stepper motor drivers and potentiometers can be affected by dust and vibration. Dust can interfere with the electrical components and cause unexpected issues. Clean the mainboard and other components regularly. Vibration can cause the potentiometers to move slightly over time, changing the VREF settings. Periodically recheck the VREF values, especially if you have noticed any changes in your print quality. To reduce the likelihood of vibration affecting the potentiometers, ensure the printer is on a stable surface and that all components are securely mounted. By including VREF checks in your regular maintenance schedule, you will maximize your printer’s performance and lifespan.

The Impact of VREF on Print Quality

The correct VREF settings have a direct impact on your Tevo Tarantula’s print quality. The correct VREF settings contribute to a variety of factors that improve your prints. This includes accuracy, precision, and the overall surface finish. Incorrect VREF settings can lead to a variety of problems. Skipped steps, for example, will cause layer shifting and dimensional inaccuracies. Under-extrusion can result from insufficient power to the extruder motor, leading to weak layers and poor adhesion. Overheating can cause the motors to fail and cause the printed object to distort. Well-calibrated VREF settings mean the motors provide the correct amount of power to deliver smooth, accurate, and reliable prints. Invest the time to properly calibrate and maintain your VREF settings. The result will be a significant improvement in your 3D printing experience.