7 Benefits of Tevo Tarantula Aluminum Upgrade Kits

The Tevo Tarantula is a popular 3D printer, known for its affordability and ease of use. However, like many entry-level 3D printers, it can benefit significantly from upgrades. One of the most impactful upgrades you can make is installing an aluminum upgrade kit. This guide explores the top seven benefits of equipping your Tevo Tarantula with an aluminum upgrade kit, transforming it from a hobbyist machine into a more reliable and high-performing 3D printer.

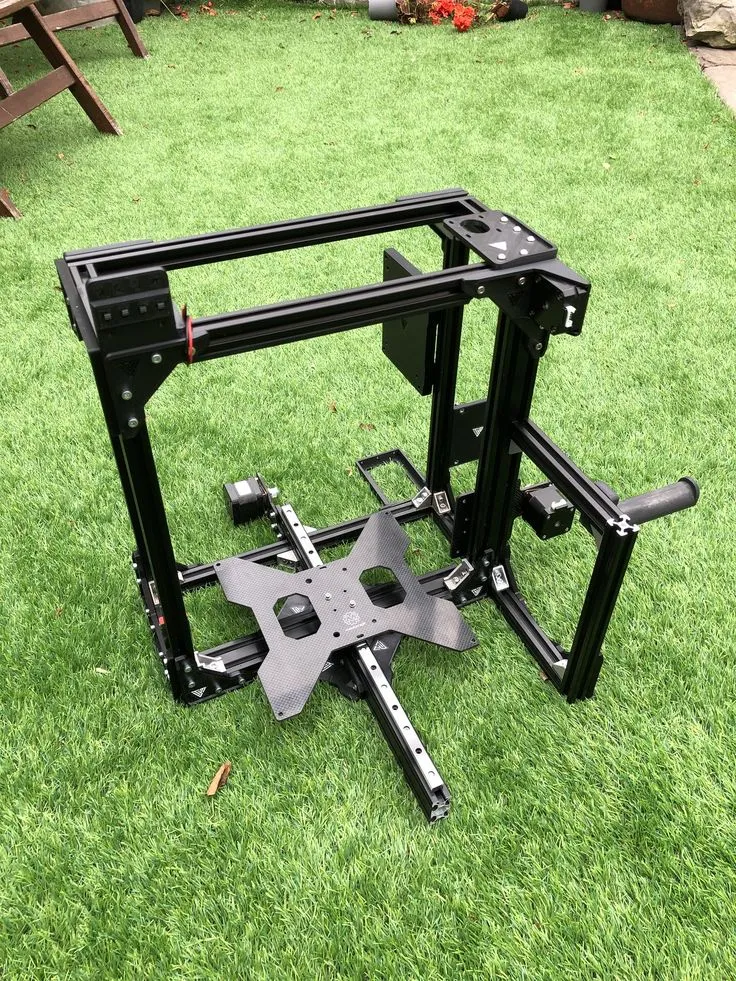

Enhanced Stability and Rigidity

One of the most immediate advantages of an aluminum upgrade kit is the increased stability and rigidity it provides. The stock Tevo Tarantula often uses plastic or composite parts, which can flex and deform during printing. Aluminum, on the other hand, is a much stiffer material, minimizing flex and ensuring that the printer’s frame remains stable throughout the printing process. This improved stability is the foundation for better print quality.

Reduced Vibration for Improved Prints

The enhanced rigidity directly translates to reduced vibrations. Vibrations are the enemy of precision 3D printing, often leading to layer shifting, ringing, and other undesirable artifacts. Aluminum components absorb and dissipate vibrations much more effectively than plastic, resulting in smoother and more accurate prints. This is especially noticeable at higher printing speeds.

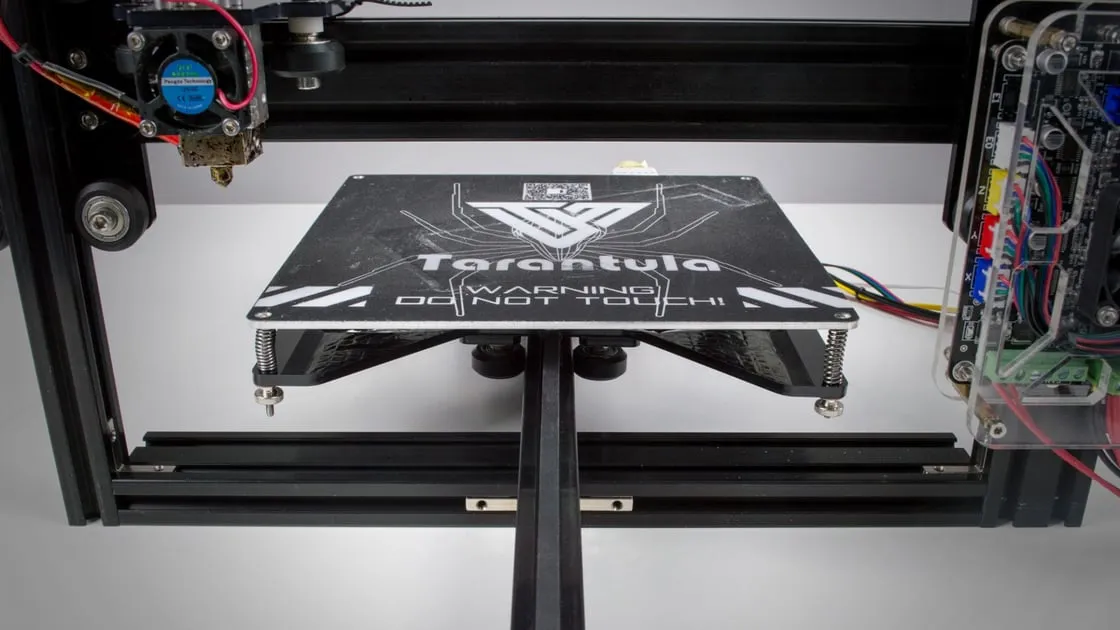

Increased Print Quality

With improved stability and reduced vibrations, the overall print quality of your Tevo Tarantula will significantly increase. You’ll notice sharper details, cleaner lines, and more accurate dimensions. The aluminum upgrade kit allows for greater precision, resulting in prints that more closely match your designs. You’ll see improvements across various aspects of your prints, from fine details to overall surface finish. Check out the difference between the printer without the upgrade and the one with upgrade.

Why Aluminum Matters for Precision

Aluminum’s properties are critical for precision printing. Its dimensional stability ensures that the printer’s frame doesn’t warp or shift due to temperature fluctuations or mechanical stress. The material’s ability to resist deformation means that the printer maintains its calibration and accuracy over time, crucial for producing consistent, high-quality prints. This makes aluminum a superior choice for the structural components of your 3D printer.

Improved Heat Dissipation

Aluminum is an excellent conductor of heat. An aluminum upgrade kit can improve heat dissipation in several areas, most notably around the hot end and the heated bed. This can lead to more consistent temperatures, which are crucial for successful 3D printing. Consistent temperatures mean fewer issues with filament warping, better layer adhesion, and improved overall print quality.

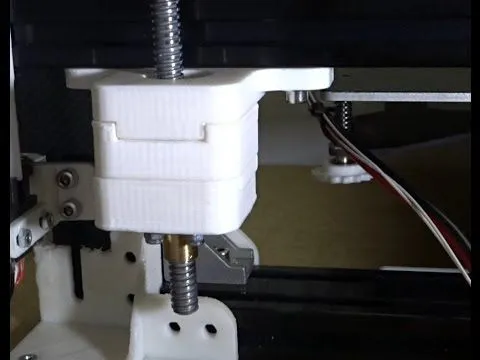

Faster Printing Speeds

Improved heat dissipation can indirectly lead to faster printing speeds. With the hot end able to maintain its temperature more effectively, you can often increase print speeds without sacrificing quality. This is because the hot end can keep up with the faster extrusion rate. Faster printing speeds can significantly reduce print times and increase your overall productivity. However, proper calibration and tuning are essential to avoid print failures.

Extended Printer Lifespan

By reducing stress on components and improving overall stability, an aluminum upgrade kit can extend the lifespan of your Tevo Tarantula. The sturdier frame and improved heat management mean less wear and tear on critical parts, such as the stepper motors and the frame itself. This upgrade helps ensure that your printer will provide reliable service for years to come, offering a better return on your investment.

Durability and Longevity

Aluminum components are generally more durable than plastic ones. They are less susceptible to cracking, warping, or breaking, even under heavy use. This durability ensures that the upgrade kit will last for a long time, providing lasting benefits to your printer. The long-term reliability of the upgrade kit contributes to the overall longevity of your 3D printing setup.

Better Filament Feeding and Extrusion

Aluminum upgrades can often improve the accuracy and reliability of the filament feeding and extrusion processes. By providing a more stable platform for the extruder assembly, the upgrade kit helps ensure that filament is fed consistently. This leads to more reliable layer adhesion and fewer extrusion problems. You may see an improvement in the overall print quality, especially when printing intricate designs.

Optimized for High-Temperature Filaments

Aluminum components can withstand higher temperatures than the stock plastic parts. This makes your printer better suited for printing high-temperature filaments such as ABS, nylon, or polycarbonate. Aluminum helps maintain stable temperatures at the hot end, preventing heat creep and ensuring reliable printing with a wider range of materials. With the upgrade, you open up a whole new world of materials to experiment with.

Easier Calibration and Maintenance

A more rigid and stable printer is easier to calibrate and maintain. The improved frame stability means that your printer’s settings are less likely to drift over time. Adjustments are more straightforward, as the frame is less prone to flex. The increased precision of the aluminum components allows for more accurate calibrations, ensuring that your printer is always performing at its best.

Simplified Adjustments

With aluminum upgrades, making adjustments to your printer becomes simpler. The solid frame means that any adjustments you make, such as leveling the bed or tightening belts, will have a more direct and lasting effect. You will spend less time re-calibrating and more time printing, leading to increased productivity and less frustration. Simplified adjustments contribute to a more enjoyable 3D printing experience.

Cost-Effectiveness and Value

While an aluminum upgrade kit represents an initial investment, it provides excellent value over the long term. By improving print quality, extending printer lifespan, and reducing the need for frequent repairs, the kit pays for itself over time. The enhanced performance and reliability of the printer make it a cost-effective upgrade for any Tevo Tarantula owner who wants to get the most out of their machine.

Understanding the Return on Investment

The return on investment (ROI) for an aluminum upgrade kit is significant. Beyond the immediate benefits of improved print quality and performance, the kit reduces downtime due to printer failures and extends the lifespan of the printer. This translates to more prints, less time spent troubleshooting, and ultimately, a better overall 3D printing experience. The ROI comes in many forms, including time saved, reduced waste, and higher-quality prints.

Long-term Savings on Parts and Replacements

By reducing wear and tear on your printer’s components, the aluminum upgrade kit can help you save money on parts and replacements over time. The sturdier frame and improved stability help prevent failures of critical parts such as the hot end, bed, and frame components. This can lead to significant cost savings and fewer disruptions to your 3D printing workflow. Investing in the upgrade kit is an investment in the long-term health of your printer.

Selecting the Right Aluminum Upgrade Kit

Choosing the right aluminum upgrade kit for your Tevo Tarantula is crucial to maximizing the benefits. Several factors should be considered to ensure that you select a kit that meets your specific needs and enhances your printer’s performance. Researching different kits and understanding their features will help you make the best decision for your 3D printing setup.

Identifying Compatibility

The first step in selecting an aluminum upgrade kit is to ensure compatibility with your Tevo Tarantula model. Check the kit’s specifications to verify that it is designed for your particular version of the printer. Some kits may be designed for specific versions or revisions of the Tevo Tarantula. Confirming compatibility will prevent potential installation issues and ensure that the upgrade kit functions as intended.

Reading Reviews and Comparing Kits

Before making a purchase, read reviews from other Tevo Tarantula owners. Reviews can provide valuable insights into the quality, ease of installation, and overall performance of different upgrade kits. Compare the features of various kits, paying attention to the materials used, the included components, and the level of support provided by the manufacturer. Use this information to determine which kit best meets your needs.

Essential Components in an Aluminum Upgrade Kit

A good aluminum upgrade kit will typically include several key components. These may include aluminum frame pieces, brackets, bed supports, and possibly improved belts and pulleys. Some kits may also include upgraded screws and hardware to ensure secure and reliable assembly. Pay attention to the materials used. Look for high-quality aluminum alloys that offer good strength and durability. Verify that the kit includes all the necessary hardware.

Installation Process and Tips

Installing an aluminum upgrade kit for your Tevo Tarantula can be a rewarding experience. The process generally involves disassembling certain parts of the printer and replacing them with the aluminum components. The exact steps will vary depending on the specific kit, but generally, the installation process is not overly complicated. Taking your time and following the provided instructions carefully will ensure a successful upgrade.

Step-by-Step Guide to Upgrading Your Tevo Tarantula

Before you start the installation process, carefully review the instructions provided with your upgrade kit. Disconnect the power and remove any filament from the printer. The specific steps will depend on the kit you’ve chosen. You’ll likely start by disassembling the existing frame components, replacing them with the aluminum parts, and then reassembling the printer. Take photos during disassembly so you can reference them when putting the printer back together. Ensure that all connections are secure and the belts are correctly tensioned.

Tools and Materials Needed

Gathering the right tools and materials before you start is essential. Common tools you’ll need include screwdrivers, Allen wrenches, and possibly a set of pliers. A level can be helpful for ensuring the frame is properly aligned during assembly. Having a clean, well-lit workspace will also make the process easier. Check the upgrade kit instructions for a specific list of tools required and have them ready before you begin.

Troubleshooting Common Issues

During installation, you may encounter some common issues. If you’re having trouble, consult the instructions or the manufacturer’s support resources. Common problems can include misalignment of components, incorrect belt tension, or loose connections. Review the instructions, double-check your work, and don’t hesitate to seek help from online forums or communities. Taking your time will help you avoid mistakes.

Calibration After Upgrade

After installing the aluminum upgrade kit, calibrating your printer is essential. The improved frame stability and rigidity mean that you may need to adjust several settings. The process will ensure that you achieve the best possible print quality. Calibration involves several steps, including leveling the bed, adjusting the Z-offset, and fine-tuning your printer’s settings.

Fine-Tuning Your Printer Settings

With the new aluminum frame in place, you’ll want to optimize your printer settings. This may involve adjusting your print speed, acceleration, and jerk settings. Experimenting with these settings can help you get the most out of your upgraded printer. Test printing a calibration cube or a simple model to identify areas where you can improve. The goal is to find the perfect balance between speed and print quality.

Optimizing Slicing Profiles

Optimizing your slicing profiles is key to getting the best results from your upgraded Tevo Tarantula. After installing the aluminum upgrade, you might be able to increase your print speed and acceleration. You will also need to fine-tune other parameters, such as layer height, infill density, and extrusion temperature. Small adjustments can have a significant impact on your print quality. Experimenting with different settings will help you to find the ideal profiles for your specific printing needs. Make sure you save different profiles for different materials and designs to maximize your results.

Conclusion

Upgrading your Tevo Tarantula with an aluminum upgrade kit is a worthwhile investment. The benefits, including improved stability, print quality, heat dissipation, and durability, are well worth the effort. By choosing the right kit, carefully following the installation instructions, and taking the time to calibrate your printer, you can transform your Tevo Tarantula into a more capable and reliable 3D printing machine. The upgrade allows you to explore more materials, print at higher speeds, and enjoy a more fulfilling 3D printing experience.