Top 5 Tevo Tarantula Pro Upgrades to Boost Performance

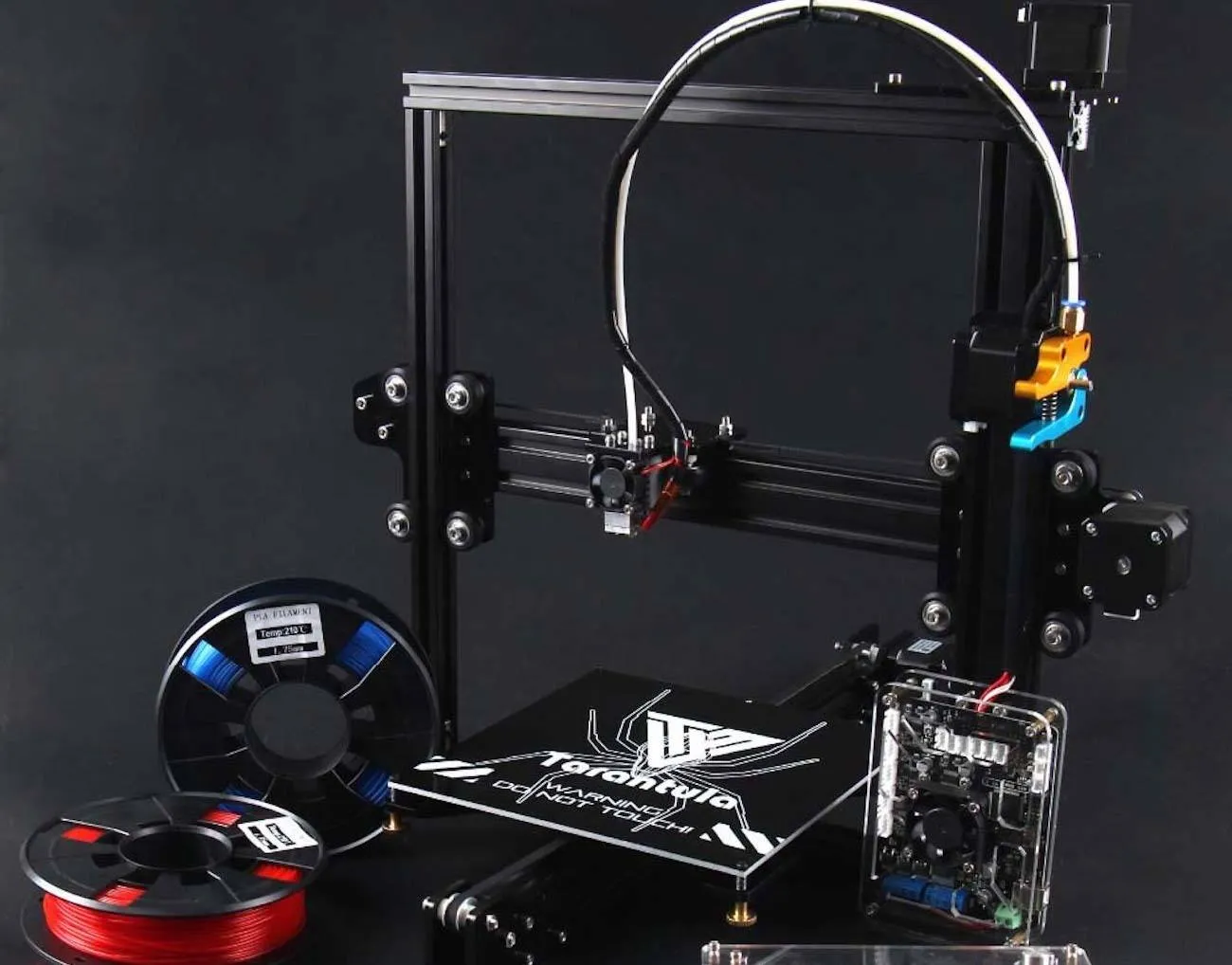

The Tevo Tarantula Pro is a popular 3D printer kit, known for its affordability and open-source design, making it a great entry point into the world of 3D printing. While it offers a solid foundation, upgrading specific components can significantly enhance its performance, print quality, and overall user experience. This guide explores the top 5 upgrades that can transform your Tevo Tarantula Pro from a good printer into a great one. By investing in these upgrades, you can reduce printing issues, improve print speed, and achieve higher quality results. Whether you’re a beginner or an experienced user, these upgrades will provide a noticeable improvement in your 3D printing capabilities, allowing you to create more complex and detailed models with ease. The following upgrades are a cost-effective way to maximize the potential of your Tevo Tarantula Pro kit.

Why Upgrade Your Tevo Tarantula Pro Kit?

Upgrading your Tevo Tarantula Pro isn’t just about adding fancy components; it’s about optimizing your printer for better performance, reliability, and print quality. The stock components, while functional, often have limitations that can hinder your printing experience. Upgrades address these limitations, offering benefits such as improved print speed, more accurate prints, and reduced printing errors. Upgrading also allows you to customize the printer to your specific needs and preferences, which can increase the lifespan of the 3D printer. Additionally, upgrades can improve the overall experience, making the printing process more enjoyable and efficient. Moreover, upgrading your printer can future-proof your investment, allowing it to adapt to advancements in 3D printing technology. By upgrading, you also gain better control over your print settings and experiment with different materials.

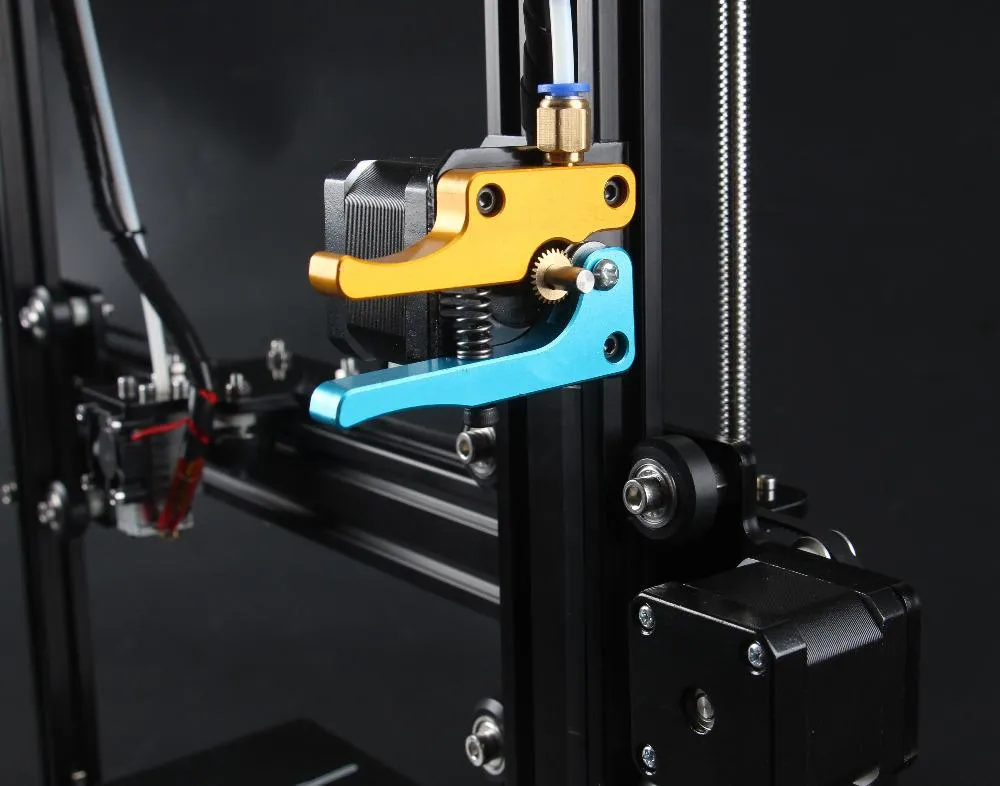

Upgrade 1 Filament Feeding System

The filament feeding system is crucial for consistent and reliable printing. The stock system on the Tevo Tarantula Pro can sometimes struggle with certain filaments or experience issues like grinding or slipping. Upgrading to a more robust feeding system can solve these problems. This often involves replacing the extruder with a geared system that provides better grip and more precise filament control. Consider an all-metal extruder. These extruders are designed to handle higher temperatures and offer better durability. They often include adjustable tensioning mechanisms that allow you to fine-tune the pressure on the filament, minimizing the risk of jams and ensuring a smooth and consistent filament flow. Choose a feeding system that is compatible with a variety of filaments. This will make your printer more versatile.

Benefits of a Better Filament Feeding

A superior filament feeding system translates directly into better print quality and reduced print failures. Improved grip on the filament ensures that the extruder can reliably push the filament through the hot end, resulting in consistent extrusion and preventing under-extrusion or inconsistent layer adhesion. With a more efficient system, you can print at faster speeds without sacrificing quality. This means you can complete projects more quickly and efficiently. Furthermore, a reliable feeding system reduces the likelihood of filament jams, which can halt printing mid-way through and lead to wasted materials and time. Ultimately, a better filament feeding system contributes to higher-quality prints with more intricate details and fewer defects, making the entire 3D printing process more enjoyable and rewarding.

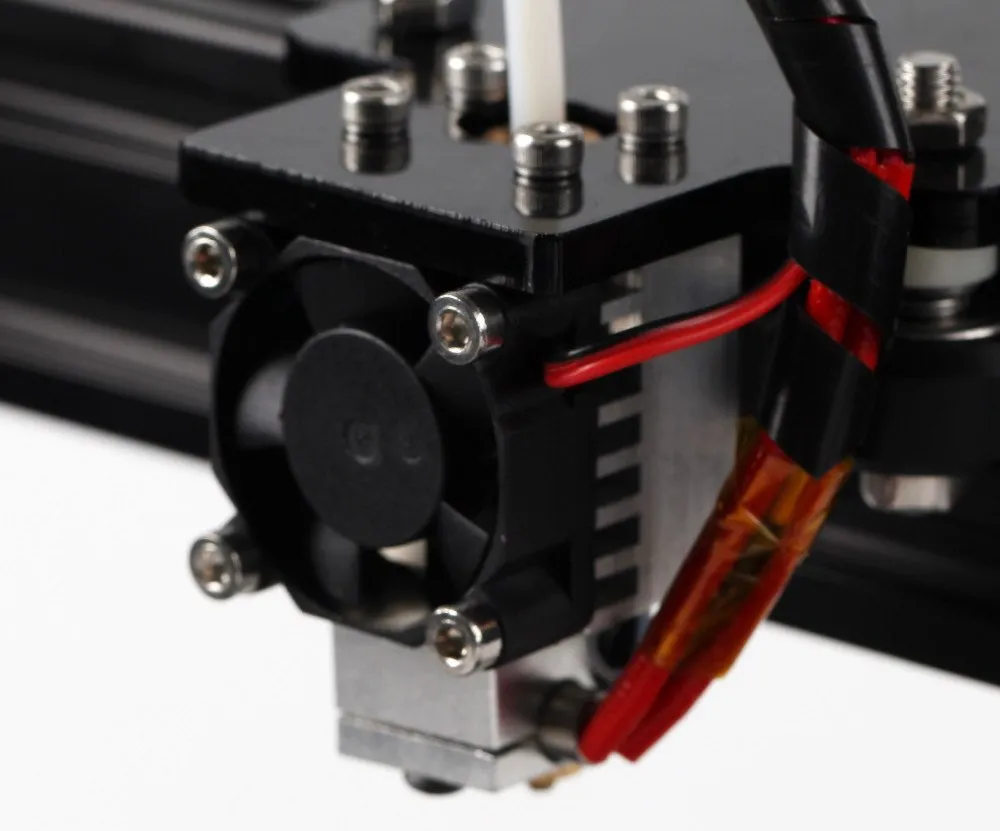

Upgrade 2 Hotend

The hotend is the heart of your 3D printer, responsible for melting and extruding the filament. Upgrading the hotend can significantly improve print quality and allow you to print with a wider range of materials. The stock hotend on the Tevo Tarantula Pro may have limitations in terms of temperature control and heat dissipation. Replacing it with an all-metal hotend or a hotend with improved thermal management capabilities can provide better temperature stability and prevent issues like filament degradation or clogging. Consider upgrading to a hotend that supports higher temperatures. This is important if you plan on printing with advanced materials like nylon or polycarbonate. Look for hotends with efficient heat breaks and nozzles to prevent heat creep and ensure a smooth and consistent flow of filament. Properly selected hotend can dramatically enhance the range of materials you can use.

Benefits of Hotend Upgrade

Upgrading your hotend offers several advantages, primarily in terms of print quality and material versatility. A more efficient hotend provides more precise temperature control, which leads to better layer adhesion and finer details in your prints. With improved thermal management, you’ll experience fewer issues like stringing, oozing, and nozzle clogs. You can print at slightly faster speeds without compromising quality. Furthermore, a higher-quality hotend opens up possibilities for using a wider variety of filaments, including those that require higher printing temperatures. You’ll also find that your prints are more structurally sound. The overall result is a significant enhancement in the quality and capabilities of your 3D printer, allowing you to achieve professional-looking prints with ease.

Upgrade 3 Bed Leveling

Bed leveling is a critical step in 3D printing, as it ensures the first layer adheres properly to the print bed. The Tevo Tarantula Pro often uses manual bed leveling, which can be time-consuming and prone to errors. Upgrading to an automatic bed leveling system (ABL) can significantly simplify the process and improve print success rates. ABL systems use sensors to measure the distance between the nozzle and the print bed at multiple points. This data is then used to automatically adjust the Z-height during printing, ensuring a consistent first layer. There are various types of ABL systems available. Some popular options include inductive sensors, capacitive sensors, and BLTouch sensors. The BLTouch is known for its accuracy and reliability. Regardless of the type of ABL, the goal is to ensure a perfectly leveled bed, which will minimize warping and ensure that the prints stick to the bed.

Why Bed Leveling is Important

Accurate bed leveling is fundamental to successful 3D printing. Without a level bed, the first layer of your print may not adhere properly. This can lead to warping, poor print quality, and failed prints. Auto-bed leveling simplifies the process and guarantees consistency. This ensures every print starts on a solid foundation, reducing the likelihood of issues and increasing the success rate. ABL saves time and frustration by automating the leveling process. It also allows you to print unattended, knowing that the printer is more likely to produce a successful result. Moreover, a well-leveled bed contributes to better overall print quality, with more precise details and smoother surfaces. It also reduces the amount of time you spend troubleshooting print failures and allows you to focus on designing and creating, rather than struggling with the printer. ABL significantly improves the reliability of your 3D printer.

Upgrade 4 Control Board

The control board is the brain of your 3D printer, managing all the operations. Upgrading the control board can unlock advanced features and improve performance. The stock control board on the Tevo Tarantula Pro may have limited processing power and memory. Replacing it with a board that has more processing power can lead to faster print speeds, smoother movements, and quieter operation. Boards based on 32-bit microcontrollers, such as the SKR Mini E3 or the MKS Gen L V2.0, are common upgrades. When upgrading, ensure the new board is compatible with your printer’s other components. Consider features like silent stepper motor drivers. This reduces noise and improves print quality. The board upgrade can also open up the possibility for firmware upgrades and advanced features, such as mesh bed leveling.

Benefits of Control Board Upgrade

Upgrading the control board provides several advantages, including improved print quality, quieter operation, and the ability to leverage more advanced features. A more powerful control board can process instructions more quickly, leading to smoother and more precise movements, reduced vibrations, and higher print speeds. Upgrading to silent stepper motor drivers significantly reduces the noise generated by the printer, making it more pleasant to operate. You also gain access to advanced features, such as mesh bed leveling, which further enhances print quality and reduces the risk of failures. By upgrading the control board, you’re essentially giving your 3D printer a performance boost and opening up new possibilities for future upgrades and customization. Furthermore, many modern control boards offer expanded memory and connectivity options, making it easier to update firmware, monitor prints remotely, and integrate with other devices.

Upgrade 5 Firmware

Firmware is the software that controls the 3D printer’s operations. Upgrading the firmware can improve performance, add new features, and fix bugs. The Tevo Tarantula Pro often comes with Marlin firmware, an open-source firmware. You can upgrade to the latest version of Marlin to take advantage of new features, bug fixes, and performance improvements. Custom firmware configurations are often possible, allowing you to tailor the printer’s behavior to your specific needs. Before upgrading the firmware, make sure to back up your current settings. This will allow you to revert to the original settings if needed. Research the firmware options and choose one that is compatible with your printer’s components and offers the features you need. Consider the features, such as linear advance and advanced print settings. Updating firmware can sometimes require flashing the firmware onto the control board. Carefully follow the instructions and ensure you have the correct files to avoid damaging your printer.

Why Firmware Matters

Updating the firmware can have a significant impact on your 3D printer’s performance and features. Firmware upgrades often include performance improvements, which can lead to faster print speeds and better print quality. Bug fixes are also part of the update, which addresses software glitches that could cause printing errors or malfunctions. New features are frequently added with firmware updates. This can include advanced settings, improved control options, or new functionalities. By keeping your firmware up to date, you ensure that your printer is running efficiently and benefiting from the latest advancements in 3D printing technology. Firmware also enables you to fine-tune your printer’s settings. This can improve the quality of your prints. Moreover, staying up-to-date with firmware upgrades contributes to the long-term reliability of your 3D printer, keeping it running smoothly and effectively.

Conclusion Upgrading Your Tevo Tarantula Pro

Upgrading your Tevo Tarantula Pro is a great way to enhance its capabilities and improve your 3D printing experience. By focusing on key areas such as the filament feeding system, hotend, bed leveling, control board, and firmware, you can unlock significant performance gains, print higher-quality models, and expand the range of materials you can use. Each of these upgrades offers unique benefits, and the best approach depends on your specific needs and budget. Remember to research thoroughly, choose compatible components, and follow the installation instructions carefully. By taking the time to upgrade your Tevo Tarantula Pro, you’ll be investing in a more reliable, versatile, and capable 3D printer. Whether you’re a hobbyist or a professional, these upgrades can make a real difference in your 3D printing workflow and the quality of your final products. You’ll find that the enhanced performance and expanded capabilities make the investment in upgrades well worthwhile, turning your Tevo Tarantula Pro into an even more valuable tool.