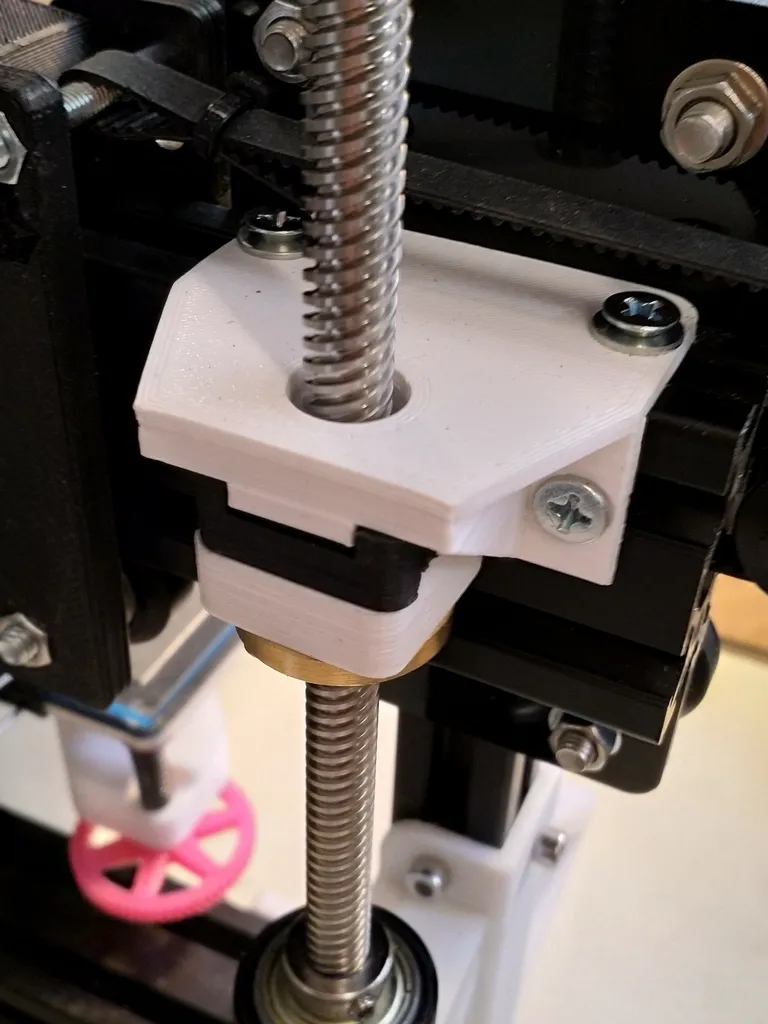

What is an Oldham Coupler?

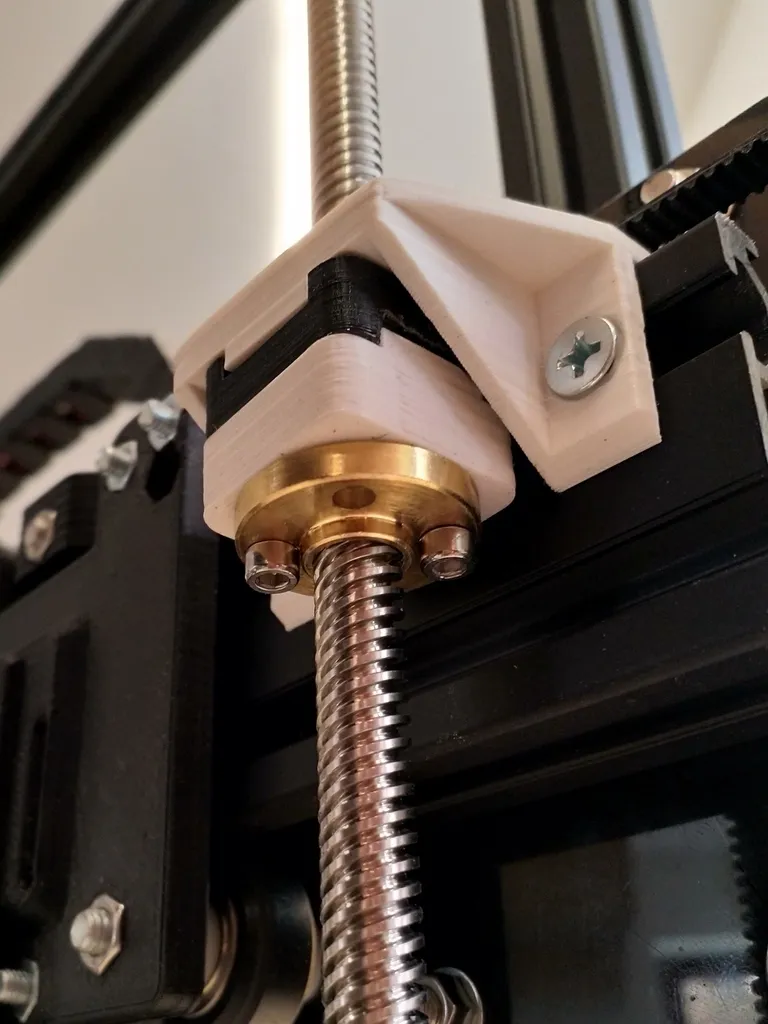

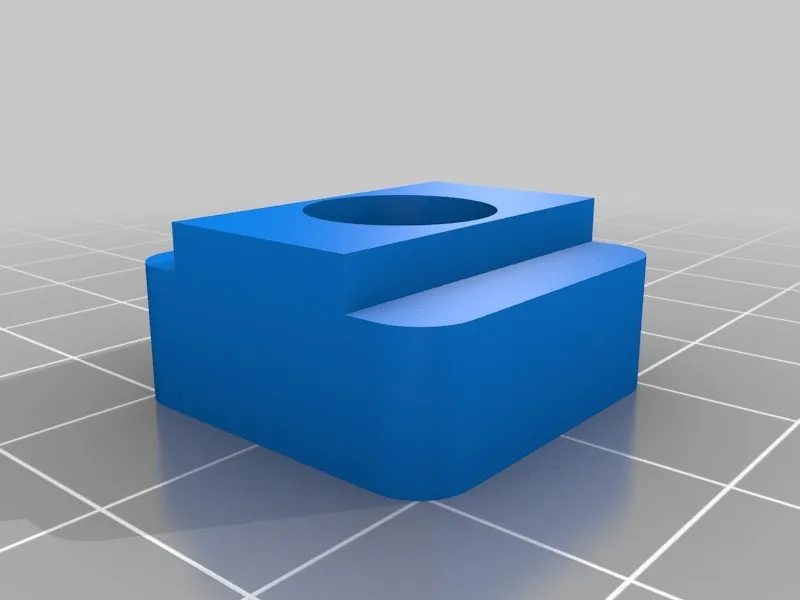

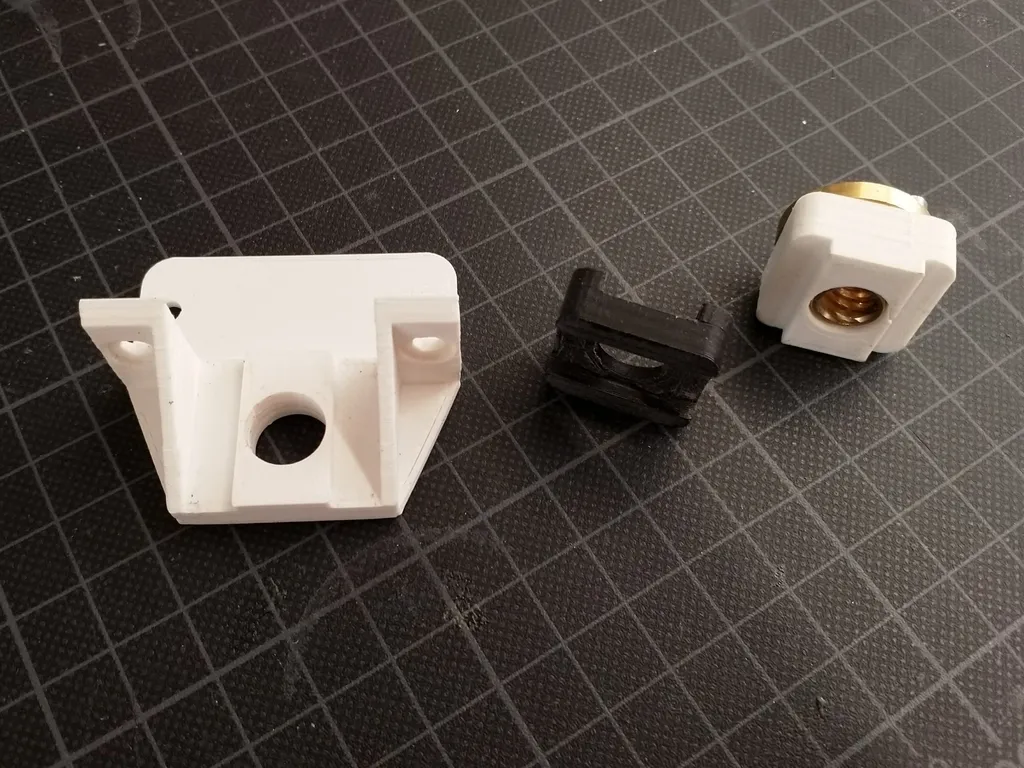

An Oldham coupler is a type of flexible coupling used in 3D printers like the Tevo Tarantula to connect the stepper motor shaft to the threaded rod (Z-axis). It is designed to compensate for any misalignment between the two shafts, which is a common issue in 3D printers due to manufacturing tolerances and assembly imperfections. The coupler consists of three parts two hubs that attach to the shafts, and a central disc or carrier that fits between the hubs. This design allows for parallel and angular misalignment while still transmitting torque. This helps to minimize vibrations and improve the overall performance of the printer by ensuring smooth and accurate Z-axis movement. Using an Oldham coupler is an upgrade that can significantly improve the print quality and reliability of your Tevo Tarantula.

Benefits of Using an Oldham Coupler

Upgrading your Tevo Tarantula with an Oldham coupler offers several advantages. One of the primary benefits is the reduction of vibrations. The flexible nature of the coupler absorbs and dampens vibrations produced by the stepper motor, resulting in smoother Z-axis movement. Another key advantage is the improvement in print quality. By compensating for any misalignment between the motor shaft and the threaded rod, the coupler helps to eliminate Z-wobble, a common printing defect that can lead to uneven layer lines. Additionally, Oldham couplers can make the calibration process easier. By providing some flexibility, they reduce the need for perfect alignment, making it simpler to get your printer set up and ready to go. Moreover, an Oldham coupler is a cost-effective upgrade that can drastically improve print quality.

Reduced Motor Vibration

One of the standout benefits of using an Oldham coupler is the reduction in motor vibrations. The inherent design of the coupler, with its flexible disc, acts as a dampener, absorbing and mitigating the vibrations generated by the stepper motor. This is especially important in 3D printing, where even slight vibrations can translate into noticeable imperfections in the printed model. By minimizing these vibrations, the Oldham coupler ensures that the Z-axis movement is smoother and more consistent, which is crucial for achieving high-quality prints. This is particularly noticeable in prints with fine details or complex geometries, where even small vibrations can lead to significant visual defects. The reduction in motor vibration is a cornerstone of improving overall print quality and the lifespan of your 3D printer.

Improved Print Quality

The use of an Oldham coupler directly contributes to improved print quality. By reducing motor vibrations and compensating for misalignment, the coupler helps to eliminate or minimize common printing defects. Z-wobble, which manifests as uneven layer lines and is a frequent issue in 3D prints, is significantly reduced because the coupler ensures a more consistent and stable Z-axis movement. This improvement in Z-axis control results in smoother surfaces, sharper details, and more accurate dimensions in your printed models. This enhancement in print quality is particularly valuable for projects that require precision or aesthetic excellence. The upgrade is cost-effective and noticeable in the final prints, making it a worthwhile investment for any Tevo Tarantula user.

Easier Calibration

Another significant advantage of using an Oldham coupler is the ease of calibration it provides. The flexibility of the coupler means that the alignment between the stepper motor shaft and the threaded rod doesn’t have to be perfectly precise. This makes the initial setup and subsequent calibration of your Tevo Tarantula much simpler and less time-consuming. Because the coupler can accommodate slight misalignments, you have more room for error during assembly, reducing the likelihood of issues caused by improper alignment. This is a particularly useful feature for users who are new to 3D printing or for those who want to streamline their printing workflow. Easier calibration leads to faster setup times and more time printing, enhancing your overall printing experience.

How to Choose the Right Oldham Coupler

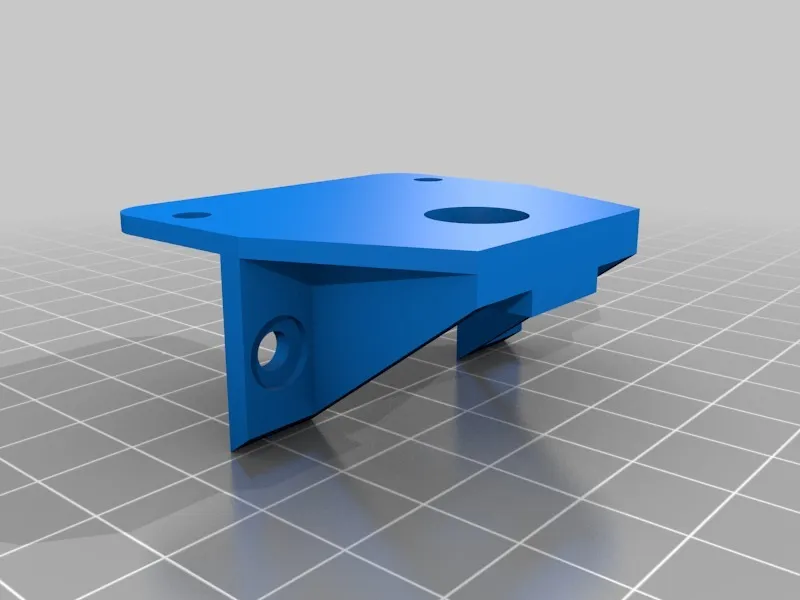

Selecting the right Oldham coupler for your Tevo Tarantula is crucial for a successful upgrade. There are a few key factors to consider to ensure you choose a coupler that will work well with your printer. First, you’ll need to pay close attention to the material of the coupler, and the size and compatibility. By understanding these factors, you can make an informed decision and get the most out of your printer upgrade.

Material Considerations

The material of the Oldham coupler is a key factor in its performance and durability. Couplers are typically made from materials like aluminum, brass, or even plastic. Aluminum couplers are a popular choice due to their balance of strength and affordability. They provide good rigidity while effectively transmitting torque. Brass couplers offer similar performance characteristics but may be slightly more expensive. Plastic couplers, on the other hand, are often the most affordable option but might not be as durable as metal alternatives, especially under high-stress conditions. Consider the types of prints you do and the overall lifespan you expect from the coupler when making your material selection.

Size and Compatibility

Size and compatibility are crucial for the proper functioning of an Oldham coupler with your Tevo Tarantula. You need to know the diameter of both your stepper motor shaft and the threaded rod to ensure that the coupler fits snugly. The coupler should be able to securely grip both components without causing any slippage. Check the specifications of the coupler to confirm it’s designed to work with your printer’s motor and threaded rod sizes. Some couplers are designed to accommodate a range of sizes, while others are more specific. Accurate measurements and careful selection will save you from potential printing issues or the need to replace the coupler due to incompatibility. This ensures that the coupler fits correctly, providing optimal performance.

Installation Tips for Your Tevo Tarantula

Installing an Oldham coupler on your Tevo Tarantula is a straightforward process, but a few key tips can ensure a smooth and successful installation. You’ll need to ensure that the printer is turned off and unplugged. Disconnect the power before beginning any modifications. This is an important safety precaution. Ensure that the stepper motor shaft and the threaded rod are clean and free of any debris. This helps to provide a solid connection between the coupler and the shafts. Take your time during the installation process, carefully following the instructions and ensuring that all components are correctly aligned. This will help to prevent issues during printing. By following these tips, you can install the Oldham coupler and improve the performance of your Tevo Tarantula.

Step-by-Step Installation Guide

Here’s a simple step-by-step guide to installing your Oldham coupler: First, disconnect the power and carefully remove the existing coupling from the Tevo Tarantula. Next, ensure the stepper motor shaft and threaded rod are clean and free of debris. Attach one of the coupler hubs to the stepper motor shaft, using the appropriate set screws to secure it firmly. Then, do the same for the other hub on the threaded rod. Finally, insert the central disc into the space between the two hubs. Make sure the hubs are aligned. Double-check all set screws to ensure they are tight, but not overly tight. Over-tightening can damage the coupler or the motor shaft. Test the Z-axis movement manually to ensure it moves smoothly. If all steps are correctly executed, you are ready to print.

Tools You’ll Need

Before starting the installation, gather all the necessary tools. Typically, you’ll need a set of Allen wrenches, a small screwdriver, and possibly a pair of pliers. The Allen wrenches are used to tighten the set screws on the coupler hubs, ensuring a secure connection to the motor shaft and threaded rod. A small screwdriver may be needed to help align or position the coupler during installation. Pliers can be useful to gently grip and manipulate components if needed. Having all the necessary tools on hand will streamline the installation process, saving you time and preventing frustration. Make sure that the tools you have are the right size.

Common Problems and Solutions

Even with the best preparation, you might encounter a few common problems during the installation or operation of your Oldham coupler. The most common issue is improper alignment. Make sure that the stepper motor shaft and threaded rod are properly aligned, and that the coupler hubs are secured firmly. Slippage can occur if the set screws are not tightened enough. Over-tightening can damage the coupler or the motor shaft. Regularly inspect your coupler for wear and tear. If you notice any damage, such as cracks or excessive play, replace the coupler immediately. By being aware of these common problems and their solutions, you can ensure the smooth operation and longevity of your upgraded Tevo Tarantula.

Troubleshooting Print Issues

If you encounter print quality issues after installing the Oldham coupler, the first step is to verify that all connections are secure. Loose connections can result in poor print results. Then, check for any play in the Z-axis movement. If there is play, try tightening the set screws or realigning the coupler. Ensure that the printer’s Z-axis is properly calibrated. Even with a good coupler, incorrect calibration can lead to print defects. If the problems persist, carefully inspect the coupler itself for any signs of damage or wear. You may need to replace the coupler. By systematically addressing these troubleshooting steps, you can diagnose and resolve most print quality issues related to the Oldham coupler.

Maintaining Your Oldham Coupler

Proper maintenance is essential for ensuring the longevity and optimal performance of your Oldham coupler. It’s advisable to regularly inspect the coupler for any signs of wear and tear, such as cracks, damage to the central disc, or loosening of the set screws. Make sure that the set screws are tightened appropriately. Over-tightening can damage the components, while under-tightening can lead to slippage. During regular maintenance, consider cleaning the coupler and surrounding area from dust and debris, which can affect its performance. By following these maintenance tips, you can extend the life of your Oldham coupler, ensuring that your Tevo Tarantula continues to produce high-quality prints. The maintenance is not very extensive, but it is very helpful.